The Ritemp System has International Patents applicable. Persons or Organizations who are found to be in breach of this patents will be

prosecuted to the full extent of the International patent laws. © Copyright Ritemp, 2021 and "Ritemp" is a Trademark of Ritemp Pty Ltd

See Brochure

Here

Thermodynamic calculations for a mold which uses the Ritemp

TM

Conformal Cooling System

The

thermodynamics

of

a

mold

which

uses

this

system

are

very

simple.

As

a

result,

comparatively

simple

mathematical

modelling

can

be used to determine heat exchanger specifications and to make meaningful predictions of molding cycle times.

The

two

primary

factors

which

control

the

time

required

for

a

molding

to

‘cure’

are

the

wall

thickness

of

the

part

and

the

ability

of

the

mold to dissipate heat.

The ‘curing‘ time in seconds for a part of wall thickness W cm can be calculated using the following formula:-

t

c

= 1.017 x {(ρ x c / k

p

)

1/2

x W / π}

2

x Ln{4 x (T

m

-T

d

) / (T

c

-T

d

) / π}

(1)

Where

T

m

= temperature of the molten plastic material (

o

C).

T

d

= average working temperature of the molding surface (

o

C).

T

c

= temperature required at centre of the part’s wall for safe ejection from the mold (

o

C).

ρ = density of the plastic material (gm/cm

3

) (At the melt temperature)

c = specific heat of the plastic material (Joules/gm/

o

C). (At the melt temperature)

k

p

= thermal conductivity of the plastic material (Watts/cm/

o

C).

Note-

equation

(1)

is

an

approximation

derived

from

an

equation

which

contains

the

sum

of

a

highly

convergent

infinite

(Fourier)

series.

For

values

of

T

c

which

are

less

than

60%

of

T

m

,

results

are

correct

to

3

significant

figures.

This

condition

is

met

for

all

practical

values of T

c

. Also, the assumption is made that full contact is maintained between the part and the mold.

Consider a part molded from polypropylene at a melt temperature of 230

o

C.

For polypropylene,

ρ = 0.89 gm/cm

3

c = 2.1 Joules/gm/

o

C

k

p

= 0.001138 Watts/cm/

o

C

Using 120

o

C as the value for T

c

, the curing time can then be calculated for any given combination of wall thickness and mold surface

temperature.

We then need to calculate the rate at which the plastic part gives up heat to the mold.

The amount of heat lost to the mold by a 1cm

2

section of the part is given by:-

H = (T

m

-(T

c

+T

d

) / 2) x W x p x c Joules

(2)

(For

simplicity

it

has

been

assumed

that

the

temperature

profile

through

the

wall

of

the

part

is

linear.

The

error

caused

by

this

approximation results in a slight overestimation of the value of H).

Knowing the curing time and the molding machine’s operating speeds, the total cycle time can then be estimated.

Let’s consider an example part which is 1 mm thick, molded in a mold which has its average surface temperature maintained at 45

o

C.

From

equation

(1)

the

cure

time

for

the

part

is

1.9

sec.

The

time

required

to

open

the

mold,

eject

the

part

and

close

it

again

would

account

for

say,

an

additional

2

seconds

and,

depending

on

the

size

of

the

part,

a

further

time

of

say,

0,6

seconds

would

be

required

for

filling

the

cavity.

Assuming

that

the

machine’s

screw

recovery

time

is

not

a

limiting

factor,

this

gives

an

estimated

total

cycle

time,

C, of 4.5 seconds.

From

equation

(2)

the

value

of

H

is

27.6

Joules/cm

2

.

This

heat

is

transferred

to

the

mold

in

about

1,9sec.

The

mold,

however,

has

4.5

seconds in which to dissipate that heat.

The rate of dissipation of heat by the mold, Q, is then given by

Q = H/C = 27.6 / 4.5 = 6.13 Watts/cm

2

.

Since

that

heat

is

directed

in

two

directions

(to

the

2

halves

of

the

mold)

we

can

then

deduce

that

each

half

of

the

mold

needs

to

dissipate

heat

at

the

rate

of

3.07

Watts

for

each

square

cm

of

plastic

in

contact

with

it.

(If

the

part

has

significant

ribbing

on

one

side,

then

the

sharing

proportions

would

need

to

be

adjusted accordingly). Let q be this share of the total.

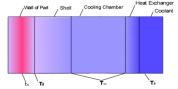

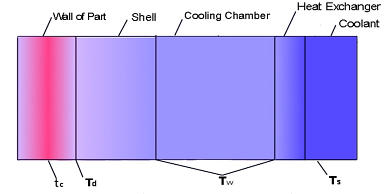

If

the

effective

distance

from

the

mold’s

working

surface

to

its

cooling

chamber

is

D

then

the

temperature

of

the

cooling

chamber

(T

w

)

will

need

to

be

maintained at a level given by the following equation:-

T

w

= T

d

– D x q / k

m

(3)

Where k

m

= Thermal conductivity of the mold material.

For a mold manufactured from P20 steel, k

m

= 3.79Watts/mm/

o

C

If D has a value of 15mm then from equation (3) the value of T

w

is 32.8

o

C.

Functional test using Demo Unit, February 2022

The demo unit has four cylindrical cores, a typical structure for the moving side of molds.

A

Ritemp

TM

Controller

was

used

to

monitor

the

cooling

chamber

temperature

(T

w

),

while

blow

torches

were

applied

to

each

core

and

iced

water

coolant

was

pumped

through

the

heat

exchanger.

The

output

of

the

torches

was

set

to

achieve

a

steady

indicated

T

w

of

35

o

C.

One

channel

of

an

accurate

2

channel

pyrometer

monitored

the

temperature

of

the

water

entering

the

heat

exchanger

while

the

other

channel monitored the water leaving it. This instrument indicated a

ΔT of 2.45

o

C.

The

coolant

flow

rate

(F)

was

determined

by

measuring

the

time

taken

for

a

measured

volume

of

coolant

to

pass

through

the

heat

exchanger.

F = 13,750 / 83 = 165.7 cc/sec

The heat dissipation rate D is then given by:-

D = F x

ΔT x 4.184 = 165.7 x 2.45

x 4.184

= 1,700 watts

.

Some of these pages UNDER CONSTRUCTION

Thermodynamic calculations for a mold which uses the Ritemp

TM

Conformal

Cooling System

The

thermodynamics

of

a

mold

which

uses

this

system

are

very

simple.

As

a

result,

comparatively

simple

mathematical

modelling

can

be

used

to

determine

heat

exchanger

specifications

and

to

make

meaningful

predictions

of

molding

cycle

times.

The

two

primary

factors

which

control

the

time

required

for

a

molding

to

‘cure’

are

the wall thickness of the part and the ability of the mold to dissipate heat.

The

‘curing‘

time

in

seconds

for

a

part

of

wall

thickness

W

cm

can

be

calculated

using the following formula:-

t

c

= 1.017 x {(ρ x c / k

p

)

1/2

x W / π}

2

x Ln{4 x (T

m

-T

d

) / (T

c

-T

d

) / π}

(1)

Where

T

m

= temperature of the molten plastic material (

o

C).

T

d

= average working temperature of the molding surface (

o

C).

T

c

= temperature required at centre of the part’s wall for safe ejection from the

mold (

o

C).

ρ = density of the plastic material (gm/cm

3

) (At the melt temperature)

c = specific heat of the plastic material (Joules/gm/

o

C). (At the melt

temperature)

k

p

= thermal conductivity of the plastic material (Watts/cm/

o

C).

Note-

equation

(1)

is

an

approximation

derived

from

an

equation

which

contains

the

sum

of

a

highly

convergent

infinite

(Fourier)

series.

For

values

of

T

c

which

are

less

than

60%

of

T

m

,

results

are

correct

to

3

significant

figures.

This

condition

is

met

for

all

practical

values

of

T

c

.

Also,

the

assumption

is

made

that

full

contact

is

maintained between the part and the mold.

Consider a part molded from polypropylene at a melt temperature of 230

o

C.

For polypropylene,

ρ = 0.89 gm/cm

3

c = 2.1 Joules/gm/

o

C

k

p

= 0.001138 Watts/cm/

o

C

Using 120

o

C as the value for T

c

, the curing time can then be calculated for any

given combination of wall thickness and mold surface temperature.

We then need to calculate the rate at which the plastic part gives up heat to the

mold.

The amount of heat lost to the mold by a 1cm

2

section of the part is given by:-

H = (T

m

-(T

c

+T

d

) / 2) x W x p x c Joules

(2)

(For

simplicity

it

has

been

assumed

that

the

temperature

profile

through

the

wall

of

the

part

is

linear.

The

error

caused

by

this

approximation

results

in

a

slight

overestimation of the value of H).

Knowing

the

curing

time

and

the

molding

machine’s

operating

speeds,

the

total

cycle time can then be estimated.

Let’s

consider

an

example

part

which

is

1

mm

thick,

molded

in

a

mold

which

has

its

average surface temperature maintained at 45

o

C.

From

equation

(1)

the

cure

time

for

the

part

is

1.9

sec.

The

time

required

to

open

the

mold,

eject

the

part

and

close

it

again

would

account

for

say,

an

additional

2

seconds

and,

depending

on

the

size

of

the

part,

a

further

time

of

say,

0,6

seconds

would

be

required

for

filling

the

cavity.

Assuming

that

the

machine’s

screw

recovery

time

is

not

a

limiting

factor,

this

gives

an

estimated

total

cycle

time,

C,

of

4.5 seconds.

From

equation

(2)

the

value

of

H

is

27.6

Joules/cm

2

.

This

heat

is

transferred

to

the

mold

in

about

1,9sec.

The

mold,

however,

has

4.5

seconds

in

which

to

dissipate

that heat.

The rate of dissipation of heat by the mold, Q, is

then given by

Q = H/C = 27.6 / 4.5 = 6.13 Watts/cm

2

.

Since

that

heat

is

directed

in

two

directions

(to

the

2

halves

of

the

mold)

we

can

then

deduce

that

each

half

of

the

mold

needs

to

dissipate

heat

at

the

rate

of

3.07

Watts

for

each

square

cm

of

plastic

in

contact

with

it.

(If

the

part

has

significant

ribbing

on

one

side,

then

the

sharing

proportions

would

need

to

be

adjusted accordingly). Let q be this share of the total.

If

the

effective

distance

from

the

mold’s

working

surface

to

its

cooling

chamber

is

D

then

the

temperature

of

the

cooling

chamber

(T

w

)

will

need

to

be

maintained

at

a

level given by the following equation:-

T

w

= T

d

– D x q / k

m

(3)

Where k

m

= Thermal conductivity of the mold material.

For a mold manufactured from P20 steel, k

m

= 3.79Watts/mm/

o

C

If D has a value of 15mm then from equation (3) the value of T

w

is 32.8

o

C.

Functional test using Demo Unit, February 2022

The

demo

unit

has

four

cylindrical

cores,

a

typical

structure

for

the

moving

side

of

molds.

A

Ritemp

TM

Controller

was

used

to

monitor

the

cooling

chamber

temperature

(T

w

),

while

blow

torches

were

applied

to

each

core

and

iced

water

coolant

was

pumped

through

the

heat

exchanger.

The

output

of

the

torches

was

set

to

achieve

a

steady

indicated T

w

of 35

o

C.

One

channel

of

an

accurate

2

channel

pyrometer

monitored

the

temperature

of

the

water

entering

the

heat

exchanger

while

the

other

channel

monitored

the

water

leaving it. This instrument indicated a

ΔT of 2.45

o

C.

The

coolant

flow

rate

(F)

was

determined

by

measuring

the

time

taken

for

a

measured volume of coolant to pass through the heat exchanger.

F = 13,750 / 83 = 165.7 cc/sec

The heat dissipation rate D is then given by:-

D = F x

ΔT x 4.184 = 165.7 x 2.45

x 4.184

= 1,700 watts

.